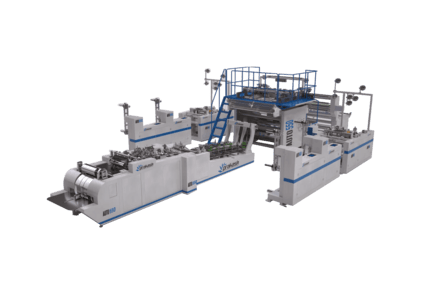

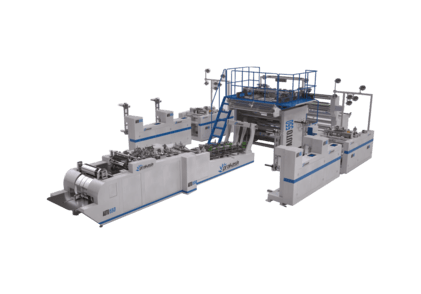

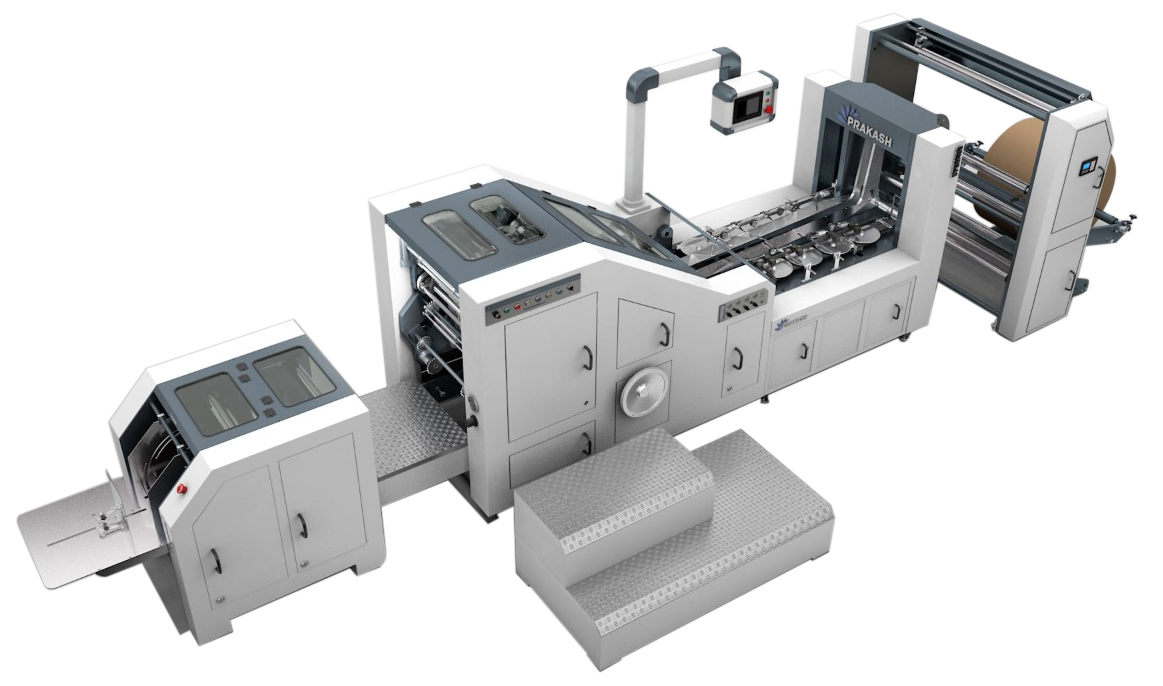

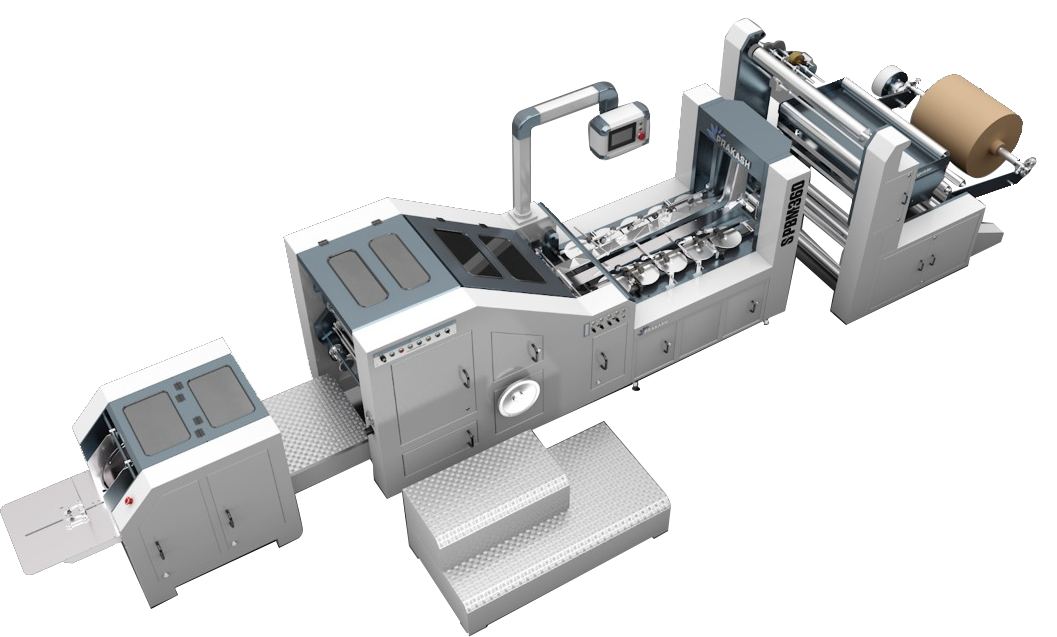

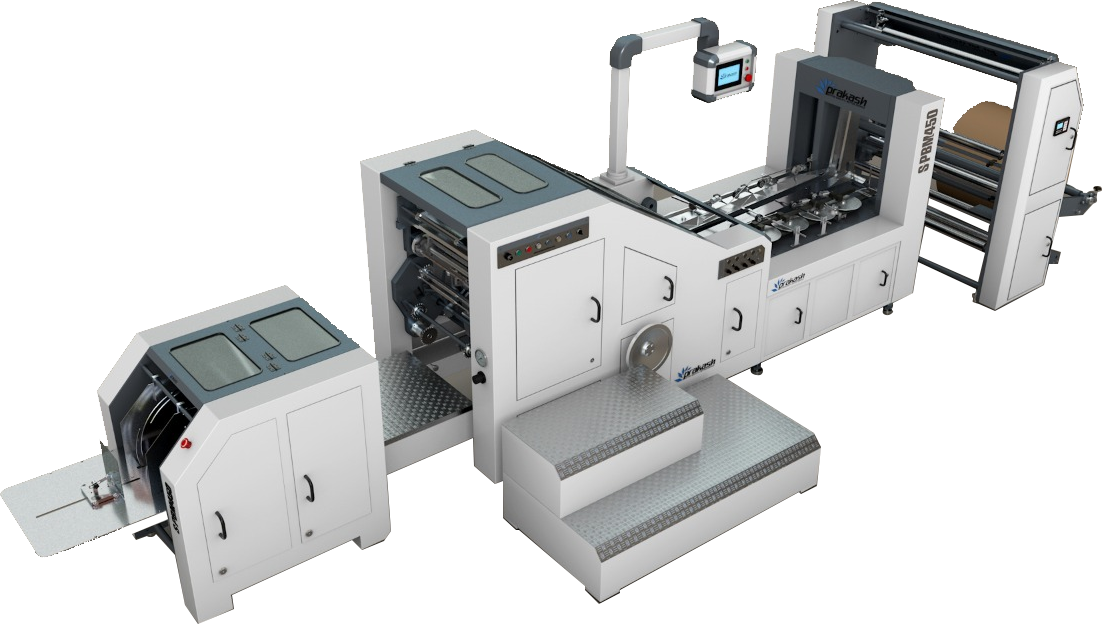

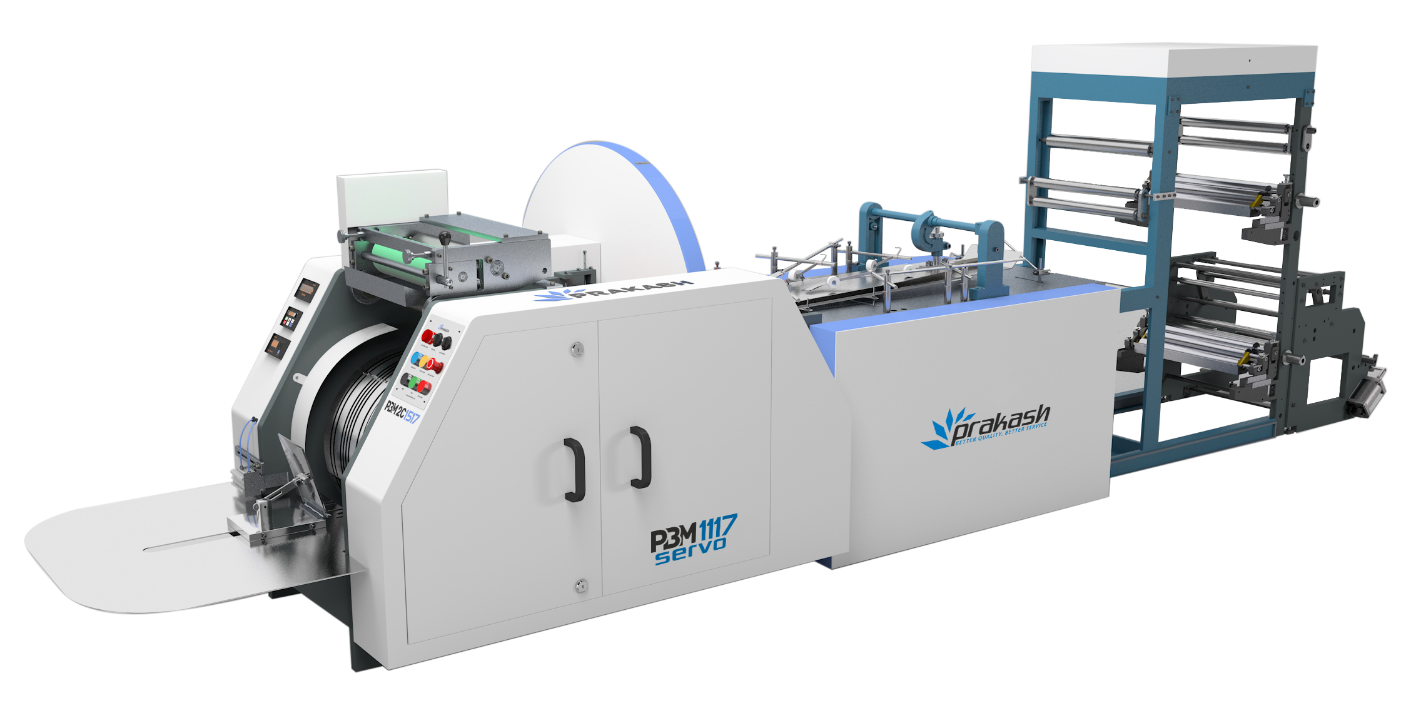

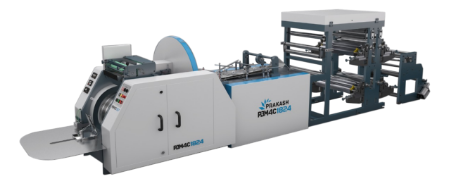

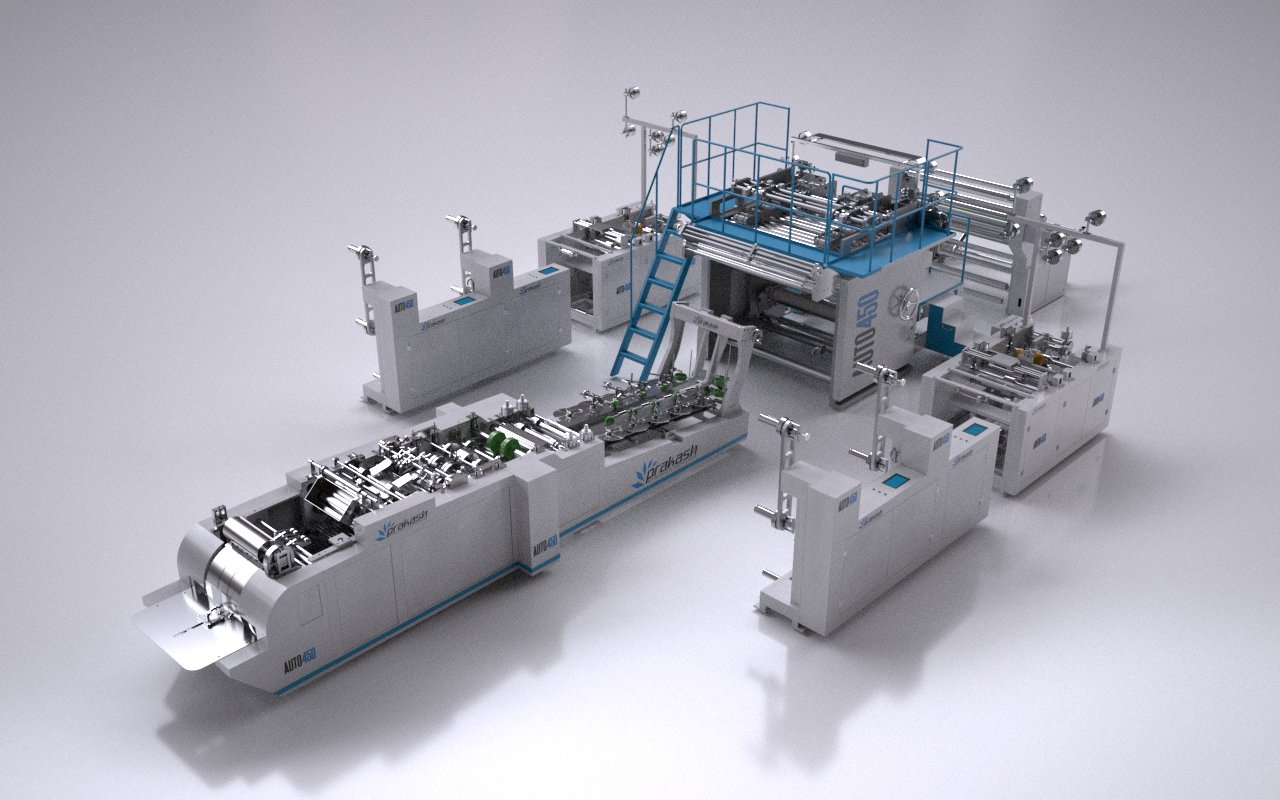

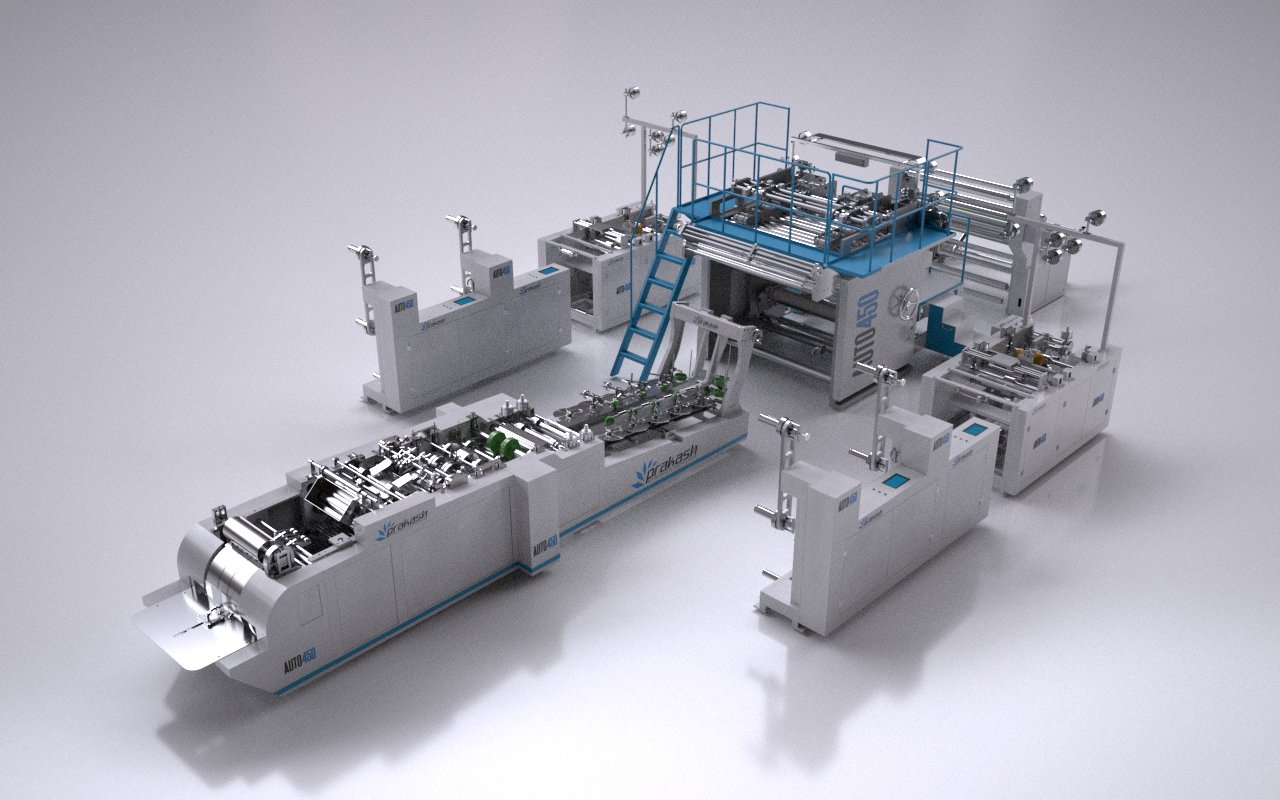

Fully Automatic Square Bottom Paper Bag Making Machine

Introduction

This is a special paper bag making machine for the production of shopping bags (block bottom bags) with twisted rope handles or flat belt handles made of paper. The material can be paper roll or printed paper roll. Whole machine is controlled by a computer central control system with touch screen and servo motor for cut-off length control. lt can produce variable size paper bags and paste paper handles inline for. complete paper bags ready for market without any manual process. The machine automatically feeds paper from roll, tube forming, cut-off, bottom forming, bottom glue, bag forming and final bag output. All steps are completed in-line; This machine is ideal equipment for Twisted or Flat handle square bottom paper bags.

Our packaging machines are trusted and used in numerous countries, including India, United Arab Emirates, United States, Bangladesh, Nigeria, Germany, Canada, United Kingdom, Sri Lanka, Saudi Arabia, Nepal, Egypt, Uganda, Japan, Vietnam, Qatar, France, Philippines, Ethiopia, Kenya, Brazil, Turkey, Pakistan, Australia, South Africa, Singapore, Italy, Spain, Ghana, Tanzania, Lebanon, Hong Kong, Taiwan, Colombia, Algeria, Jordan, Ireland, Mauritius, Libya, Russia, Malaysia, Netherlands, Oman, Zambia, Morocco, Serbia, Tunisia, Somalia, South Korea, Ukraine, Iraq, Iran, Greece, Czechia, New Zealand, Finland, Georgia, Slovenia, Azerbaijan, Rwanda, Botswana, Zimbabwe, Cameroon, Gambia, Togo, Burkina Faso, Poland, Romania, Thailand, Peru, Venezuela, Bulgaria, Cambodia, Switzerland, Kuwait, Hungary, Myanmar (Burma), Guatemala, Mongolia, Albania, Syria, and Yemen.

By delivering reliable, efficient, and innovative solutions, we ensure our clients worldwide achieve their sustainability and production goals.

| Specifications | AUTO-360 | AUTO-450 | AUTO-550 |

|---|---|---|---|

| Paper Roll Width | 460-1110 MM | 650-1330 MM | 670-1670 MM |

| Paper Bag Width | 135/180-360 MM | 230-450 MM | 240-550 MM |

| Bottom Size | 80-180 MM | 80-200 MM | 80-280 MM |

| Bag Cutting Length | 270-530 MM with handle height |

270-630 MM with handle height |

380-780 MM with handle height |

| Paper Thickness | 50-150 GSM | 65-150 GSM | 90-150 GSM |

| Handle Height | 90-120 MM | 90-120 MM | 90-120 MM |

| Diameter of Core | 76 MM | 76 GSM | 76 GSM |

| Lenght of Twisted Rope (Customizable) |

145-165 MM | 155-175 MM | 155-175 MM |

| Diameter of Twisted Rope | 3-6 MM | 3-6 MM | 3-6 MM |

| Handle Patch Lenght | 35-50 MM | 35-50 MM | 35-50 MM |

| Handle Patch Roll Diameter | 1000 MM | 1000 MM | 1000 MM |

| Paper Patch Roll Width | 70-100 MM | 70-100 MM | 70-100 MM |

| Paper GSM for Handle Patch | 80-150 GSM | 80-150 GSM | 80-150 GSM |

| Max Speed* | 100-150 Bags/Min | 100-150 Bags/Min | 100-150 Bags/Min |

| Power | 30 KW | 33 KW | 42 KW |

| Weight | 18000 KG | 19000 KG | 23000 KG |

| Machine Dimension (L*W*H) | 13500x5700x2500 MM | 14500x5800x2500 MM | 15500x6200x2500 MM |

Our fully automatic square bottom paper bag making machine is ideal for the production of shopping bags equipped with twisted rope handles or flat belt handles. This machine produces different shopping bags, grocery bags, food bags, and other paper bags available in variable sizes. Our hi-tech machines are built using the most up-to-date manufacturing method guaranteeing consistent quality and finish. The machine is controlled by a computer central control system with a touch screen and servo motor for cut-off length control. This special machine produces paper bags in one process from the printed or unprinted roll paper. The process includes side gluing, roll folding, roll paper cutting, bottom folding, bottom gluing forming, and bag formation.

The paper bag making machine is controlled by PC programmable servo motor with a simple touch. It can manufacture various sizes of a paper bags, and paste paper handle inline for completely paper bags without any manual process. The size of the paper bag can be easily changed by changing the gear and it controls the length of the bag precisely. However, a change in size is very easy and it can be done in no time. The machine performs quite incredibly because of its rugged structure and high-quality components. All the components are made on highly precise CNC machines and the correct metallurgy of the components ensures the durability of the machine. Contact now to know about Paper Bag Machine Price.

Options

- Dual Mould Technology

- Hot & Cold glueing option

- Full servo control, plc & touchscreen

- Automatic tension Control & web guide

- Fully Internet Enabled